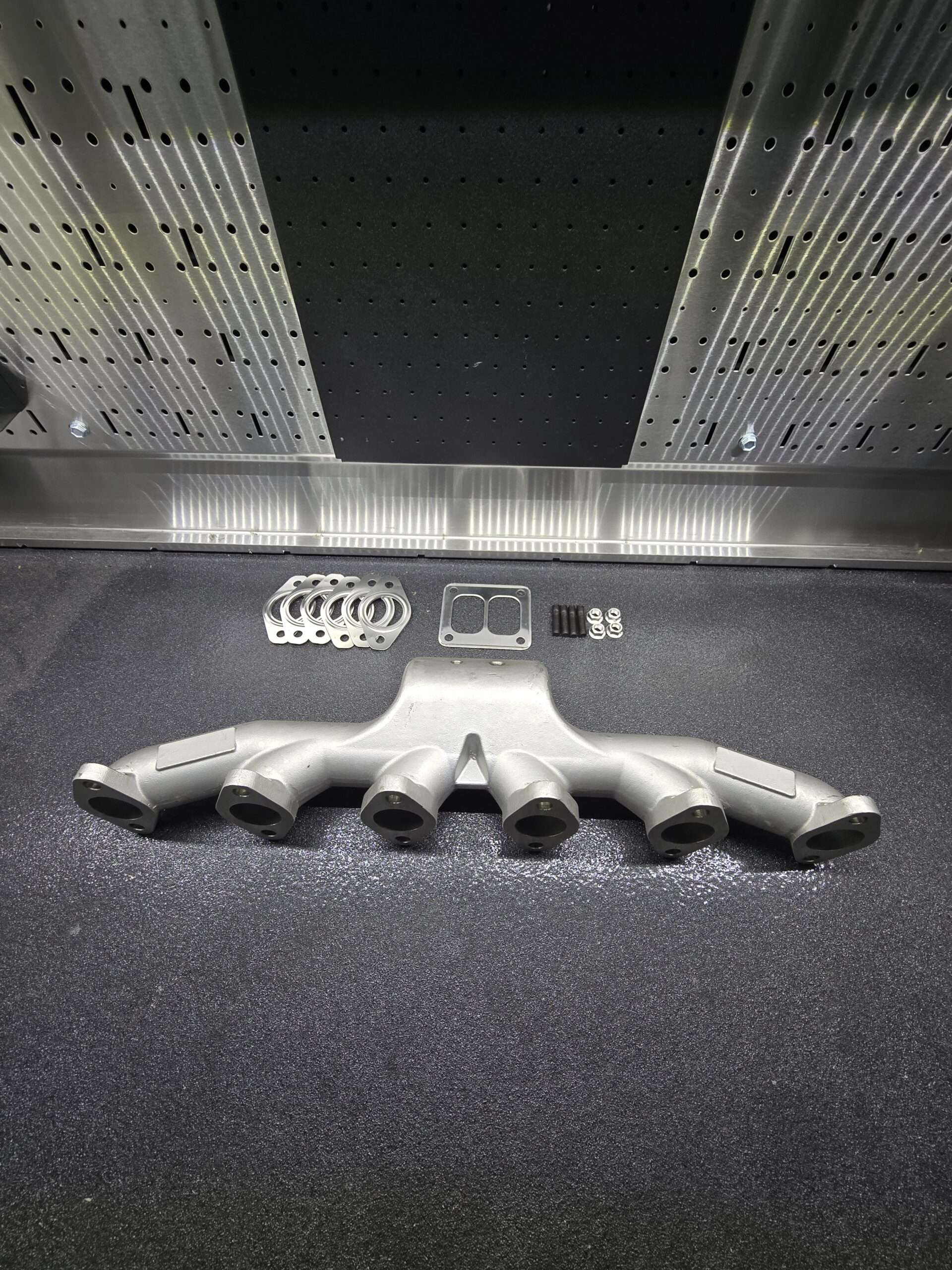

T4 24V SECOND GEN STAINLESS STEEL EXHAUST MANIFOLD 1998.5-2024 24V CUMMINS SWAP MANIFOLD

$475.00 – $575.00

This is Our Stainless Steel T4 24v Exhaust manifold. They are made with shell molding for a Super Smooth inside and out casting technology that has superior flow over and above the old type 60 grit sand paper like looking and feeling casting that all the Cast Iron exhaust manifolds are made from. Back to back testing on these manifold have shown a 20hp increase over other competitors 3 piece cast iron design manifold.

These Manifolds makes larger chargers more Drivable. Improves Horsepower and Widens Powerband. Excellent Fit & Finish. Ships With Turbo mounting Hardware and Brass 1/8 & 1/4 NPT Plugs . Increased Economy When Installed W/Same Mods. This Stainless Steel exhaust manifold was casted with a Stainless Steel moon metal mix made for Extreme High Heat cycles. These Manifolds are built with 3/4+ inch thick center section with room for Extra porting . Thick wall castings for Great Thermal control . The Super Smooth inside runner sizing is 1.650 inches all the way to the center outlet for Extreme high flow. Proven smooth single piece cast design, that has no steps that block flow in the middle like the old style 2 & 3 piece iron manifolds. The old style 2 & 3 piece iron manifolds are built with steps in the runners causing Inefficient Turbulent Air Flow Inside.

This is our Budget Friendly Option for the guys who dont want to spend the extra money on a Steed Speed T4 24v Second Gen manifold. Or if we are out of stock or you cant find one in the timely matter you need. This is a Super Great alternative for that and is very affordable! Comes with install gaskets. This manifold is optioned with or without our Manifold Stud Kit. This Manifold should work for All High Mount T4 2nd gen swaps with a 1/2″ spacer.

Manifold Stud Install Instructions! use a Neversieze or ARP lube on both end of the Stud. Finger Tighten the Studs till bottomed out. No tighter. Finger tight is enough! then install gaskets and manifold. Install Washers! Then thread all Manifold Stud NUTS on till manifold is flush and snug against the head. Then start in the MIDDLE and work your way out to each end of the manifold TORQUING to 55FT LBS. Go over them a SECOND TIME Starting in the middle and working your way out to the ends. Drive the truck for 1 or 2 days then go back over the Manifold Nuts again at 55Ft LBS starting in the middle and working your way out to the ends. check turbo nuts while you are there as well. Then forget about them! They will stay tight if you follow these steps and will never come loose!!!